Polypropylene (PP) Woven Geotextile

Classification :

PRODUCT DETAILS

A robust, layer-installed material specifically engineered for geotechnical applications. Manufactured using weaving techniques from slit film or monofilament Polypropylene (PP) yarns. PP is a thermoplastic polymer synthesized from the polymerization of propylene monomers.

Key Specifications

| Material | Polypropylene resin (PP) |

| Structure | Woven fabric construction |

| Density | Approximately 0.91 g/cm³, making it lighter than materials like polyester (PET, ~1.38 g/cm³)This results in greater coverage area per unit weight at equivalent strength levels |

| Chemical Stability | Exhibits excellent resistance to acids and alkalis, performing particularly well in alkaline environments compared to polyester (PET) |

| Puncture Resistance | PP geotextiles demonstrate superior puncture resistance properties compared to PET geotextiles of similar mass per unit area, especially relevant for protecting geomembranes |

| Tensile Strength | The woven structure provides high tensile strength, suitable for applications requiring significant load distribution or reinforcement |

Primary Characteristics:

High Strength: Offers excellent mechanical properties and tensile strength due to its woven structure.

Lightweight: Low density provides logistical and handling advantages.

Superior Chemical Resistance: Highly resistant to most acids, alkalis, and organic solvents, ensuring long-term durability in harsh soil and environmental conditions.

Good Puncture Resistance: Effectively protects underlying materials like geomembranes from damage by sharp objects (e.g., gravel, stones).

Separation Function: Prevents the intermixing of different soil layers or aggregate materials.

Filtration/Transmissivity: Controls water flow while preventing soil particle migration (specific permeability characteristics depend on weave density and yarn type).

Durability: Resistant to biological degradation (rot, mildew) and UV degradation (especially with stabilizers).

Applications

Geomembrane Protection: Widely used as puncture protection layers for geomembranes in landfills, canals, reservoirs, and containment applications.

Separation: Preventing subsoil contamination of aggregates in roads, railways, embankments, and paved/unpaved areas.

Reinforcement: Providing tensile strength and stability in soil structures like reinforced walls, slopes, and embankments (though often used with geogrids for primary reinforcement).

Filtration/Drainage: Acting as a filter layer in drainage systems, behind retaining walls, around landfill leachate collection pipes, and in erosion control structures.

Erosion Control: Used in shoreline protection, riverbank revetments, and under riprap.

Infrastructure: Applications in airport runways, parking lots, and construction platforms.

Specialized Forms: Fabricated into tubes or bags for hydraulic filling in dewatering, shoreline protection, or containment structures.

Hydraulic & Environmental Engineering: Used in tailings dam filtration layers (resistant to chemical clogging), pond linings, and as a base layer for artificial reefs.

PACKING AND DELIVERY

At present, our products are exported to Southeast Asia, Africa, the Middle East, South America and other 50 countries and regions, looking forward to cooperating with you!

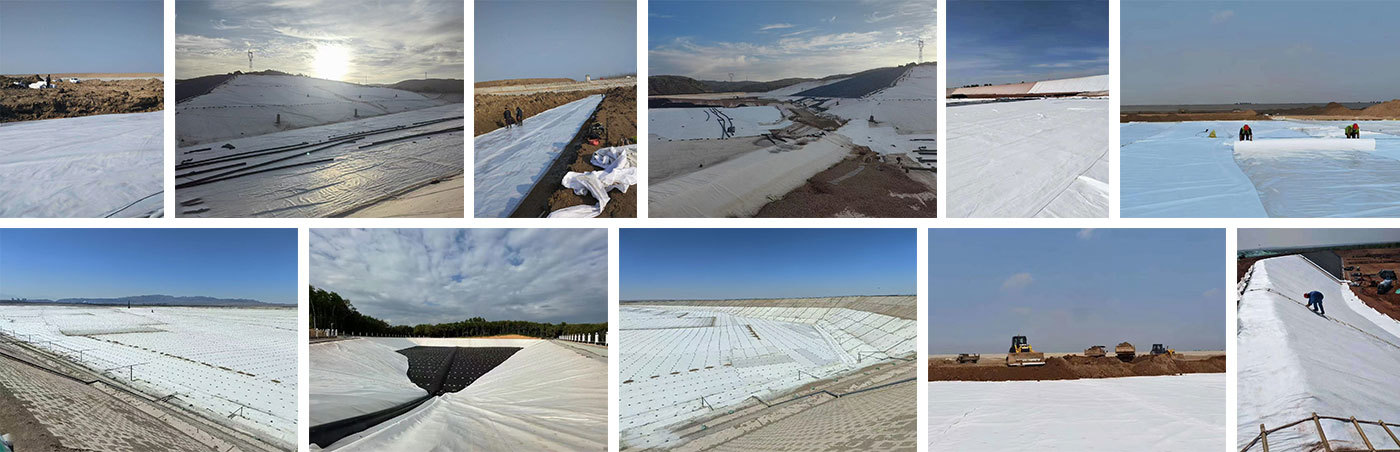

CONSTRUCTION CASES

Construction Cases

Construction Cases

Construction Cases

Construction Cases

Construction Cases

Construction Cases

FACTORY WORKSHOP

Geo-membrane blown film equipment

Geotextile Equipment

Geotextile Equipment

Quality Inspection

Geotextile Equipment

Workshop Equipment

Geo-membrane blown film equipment

Geo-membrane blown film equipment

FAQ

Q: How is the product packaged?

Q: Is there quality inspection before loading?

Q: What are the loading ports?

Q:Can you deliver the goods on time?

Q: Can we take some samples? Any fees?

How can we guarantee quality?

RELATED PRODUCTS

GET A FREE QUOTE