Polypropylene biaxial geogrid

Classification :

PRODUCT DETAILS

Polypropylene biaxial geogrid is made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

PP Plastic Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost.

PP Plastic Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill.

Specification

| Specification | Test Method | BX1515 | BX2020 | BX2525 | BX3030 | BX4040 | BX1100 | BX1200 | BX3030L | |||||||||

| Index | Unit | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | |

| Ultimate Tensile strenth | D6637 | KN/m | 15 | 15 | 20 | 20 | 25 | 25 | 30 | 30 | 40 | 40 | 12.4 | 19.0 | 19.2 | 28.8 | 30 | 30 |

| Aperture Size | mm | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 39 36 33 31 | 25 | 33 | 25 | 33 | 65 | 65 | |

| Minimum Rib Thickness | mm | 1.0 | 0.8 | 1.5 | 1.1 | 1.8 | 1.4 | 2.2 | 1.7 | 2.5 | 2.0 | 1.0 | 0.8 | 1.4 | 1.27 | 1.7 | 1.5 | |

| Tensile Strength @2% Strain | D6637 | KN/m | 6 | 6 | 7 | 7 | 9 | 9 | 11 | 11 | 15 | 15 | 4.1 | 6.6 | 6 | 9 | 11 | 11 |

| Tensile Strength @5% Strain | D6637 | KN/m | 11 | 11 | 13 | 13 | 17 | 17 | 21 | 21 | 27 | 27 | 8.5 | 13.4 | 11.8 | 19.6 | 21 | 21 |

| Junction Efficiency | % | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |||||||||

| Flexural Stiffness | D7748 | mg-cm | 690,000 | 780,000 | 860,000 | 960,000 | 1,000,000 | 250,000 | 750,000 | 960,000 | ||||||||

| Aperture Stability | m-N/deg | 0.30 | 0.50 | 0.62 | 0.75 | 0.85 | 0.32 | 0.65 | 0.75 | |||||||||

| Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | |||||||||

| Resistance to Long Term Degradation | % | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |||||||||

| Resistance to UV Degradation | D4355 | % | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||||||||

| Minimum Cabon Black | % | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |||||||||

| Unit Weight | g/m2 | 175-210 | 220-250 | 260-300 | 300-340 | 450-500 | 180-210 | 280-310 | 320-360 | |||||||||

| Rolls Dimensions (Length, Width) | m | 100*3.95 100*5 100*5.95 | 50*3.95 50*5 50*5.95 | 50*3.95 50*5 50*5.95 | 50*3.95 50*5 50*5.95 | 50*3.95 | 75*3.95 75*5 75*5.95 | 50*3.95 50*5 50*5.95 | 50*3.95 50*5 50*5.95 | |||||||||

PACKING AND DELIVERY

At present, our products are exported to Southeast Asia, Africa, the Middle East, South America and other 50 countries and regions, looking forward to cooperating with you!

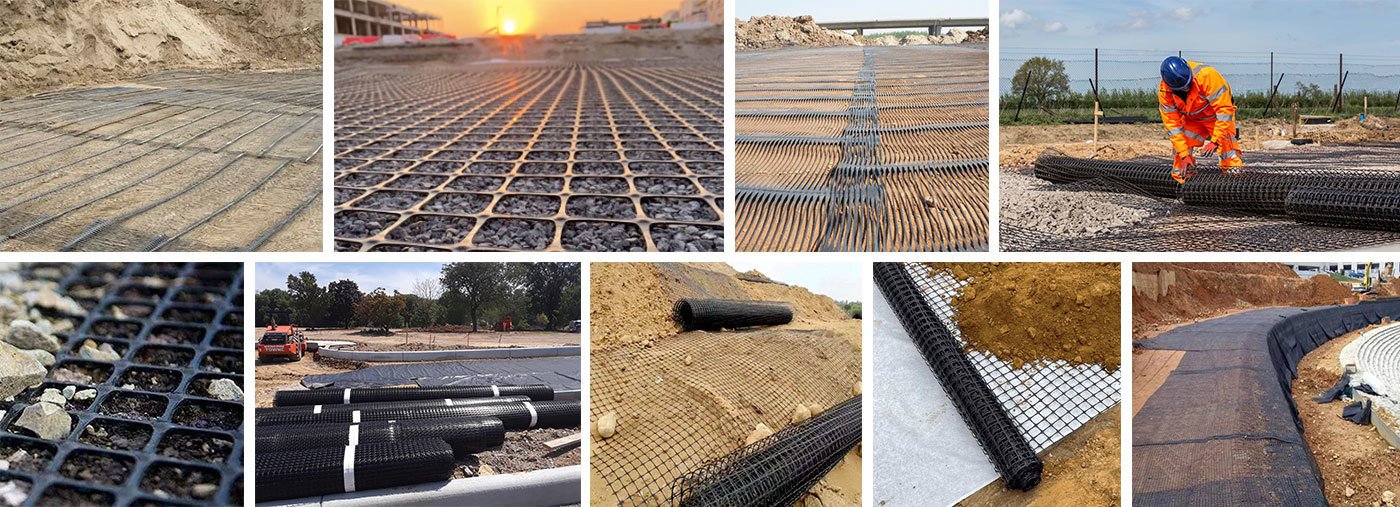

CONSTRUCTION CASES

Construction Cases

Construction Cases

Construction Cases

Construction Cases

Construction Cases

Construction Cases

FACTORY WORKSHOP

Geo-membrane blown film equipment

Geotextile Equipment

Geotextile Equipment

Quality Inspection

Geotextile Equipment

Workshop Equipment

Geo-membrane blown film equipment

Geo-membrane blown film equipment

FAQ

Q: How is the product packaged?

Q: Is there quality inspection before loading?

Q: What are the loading ports?

Q:Can you deliver the goods on time?

Q: Can we take some samples? Any fees?

How can we guarantee quality?

RELATED PRODUCTS

GET A FREE QUOTE