EVA Geomembrane

Classification :

PRODUCT DETAILS

Tunnel waterproof board production process using the domestic advanced two co-extrusion single screw extrusion method, from raw material resin by adding reinforcing agents, antioxidants, by heating and melting, plasticizing, extrusion molding, hauling the formation of the sheet, but also with a good sling geotextile heat synthesis of a composite waterproofing board, but also can be used in the extrusion and calendering method, that is, the resin extruder Banyan melting and plasticizing, extruded from the head of the slit die extrusion of the molten sheet of billet It can also use extrusion calendering method, i.e. the resin extruder will melt and plasticize, extruding the molten sheet from the slit die mouth of the machine head, fusing it with the sling, and then calendering and cooling it into a glossy film through the roller, or fusing it with the geotextile with the sling, and then calendering and cooling it into a composite waterproof sheet through the roller.

Performance Characteristics

Resistant to chemical corrosion, ultraviolet radiation; aging resistance, good abrasion resistance; strong puncture resistance; easy construction, no pollution.

Purpose of action

New railroads, highways, municipal roads, light rail transit construction (including bridge decks, tunnels), roofing, waterproofing of underground works, water conservancy construction, sewage treatment works, chemical acid and alkali treatment pools and other projects seepage corrosion-resistant, liner use.

Product specifications

Width: 2-6 meters, thickness: 1.0m-1.5mm.

Technical indicators

EVA waterproof board for tunnel GB18173.1-2012

| No. | item | unit | Technical indicators | |

| 1 | tensile strength /MPa | ordinary temperatures (23℃)≥ | Mpa | 16 |

| crystal growth (60℃)≥ | Mpa | 6 | ||

| 2 | Tensile elongation /% | ordinary temperatures (23℃)≥ | % | 550 |

| low temperatures (-20℃)≥ | % | 350 | ||

| 3 | tear strength ≥ | kN/m | 60 | |

| 4 | impermeability | 30min | 0.3MPa no leakage | |

| 5 | Low temperature bending | -35℃ uncracked | ||

| 6 | Heating Expansion | reach ≤ | mm | 2.0 |

| systolic ≤ | mm | 6.0 | ||

| 7 | Hot air aging (80℃×168h) | Tensile strength retention ≥ | % | 80 |

| Tensile elongation retention ≥ | % | 70 | ||

| 8 | Alkali-resistant [saturated Ca(OH)2 solution 23℃×168h] | Tensile strength retention≥ | % | 80 |

| Tensile elongation retention ≥ | % | 90 | ||

| 9 | artificial climate aging | Tensile strength retention ≥ | % | 80 |

| Tensile elongation retention ≥ | % | 70 | ||

| 10 | Bond peel strength (sheet to sheet) | Standard experimental conditions ≥ | N/mm | 1.5 |

| Immersion retention rate (23℃×168h)≥ | % | 70 | ||

PACKING AND DELIVERY

At present, our products are exported to Southeast Asia, Africa, the Middle East, South America and other 50 countries and regions, looking forward to cooperating with you!

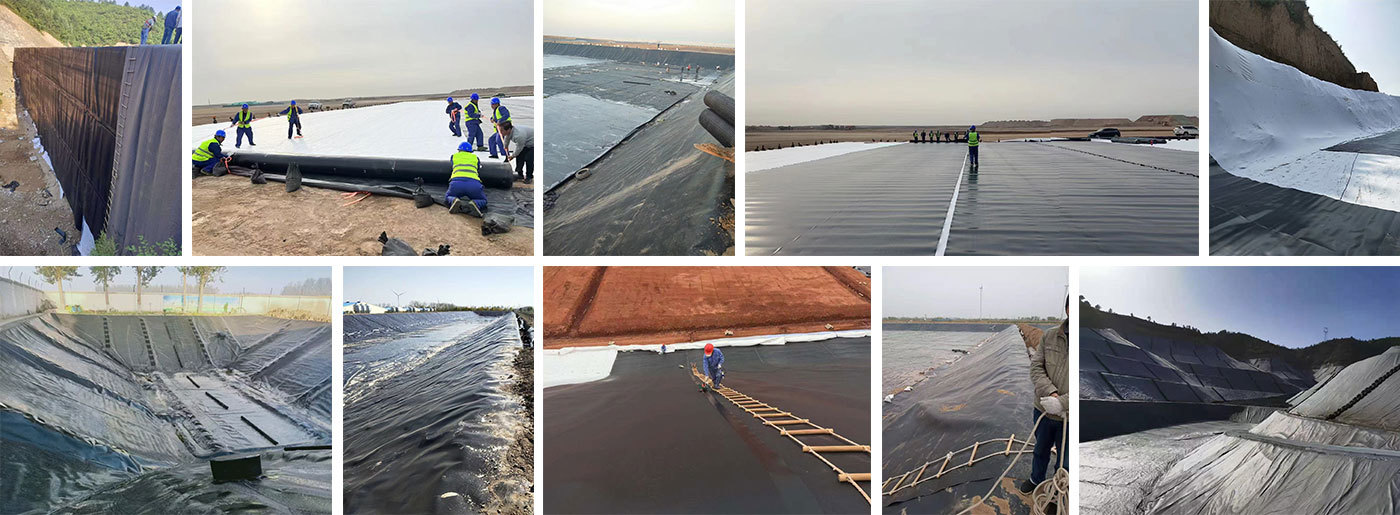

CONSTRUCTION CASES

Construction Cases

Construction Cases

Construction Cases

Construction Cases

Construction Cases

Construction Cases

FACTORY WORKSHOP

Geo-membrane blown film equipment

Geotextile Equipment

Geotextile Equipment

Quality Inspection

Geotextile Equipment

Workshop Equipment

Geo-membrane blown film equipment

Geo-membrane blown film equipment

FAQ

Q: How is the product packaged?

Q: Is there quality inspection before loading?

Q: What are the loading ports?

Q:Can you deliver the goods on time?

Q: Can we take some samples? Any fees?

How can we guarantee quality?

RELATED PRODUCTS

GET A FREE QUOTE